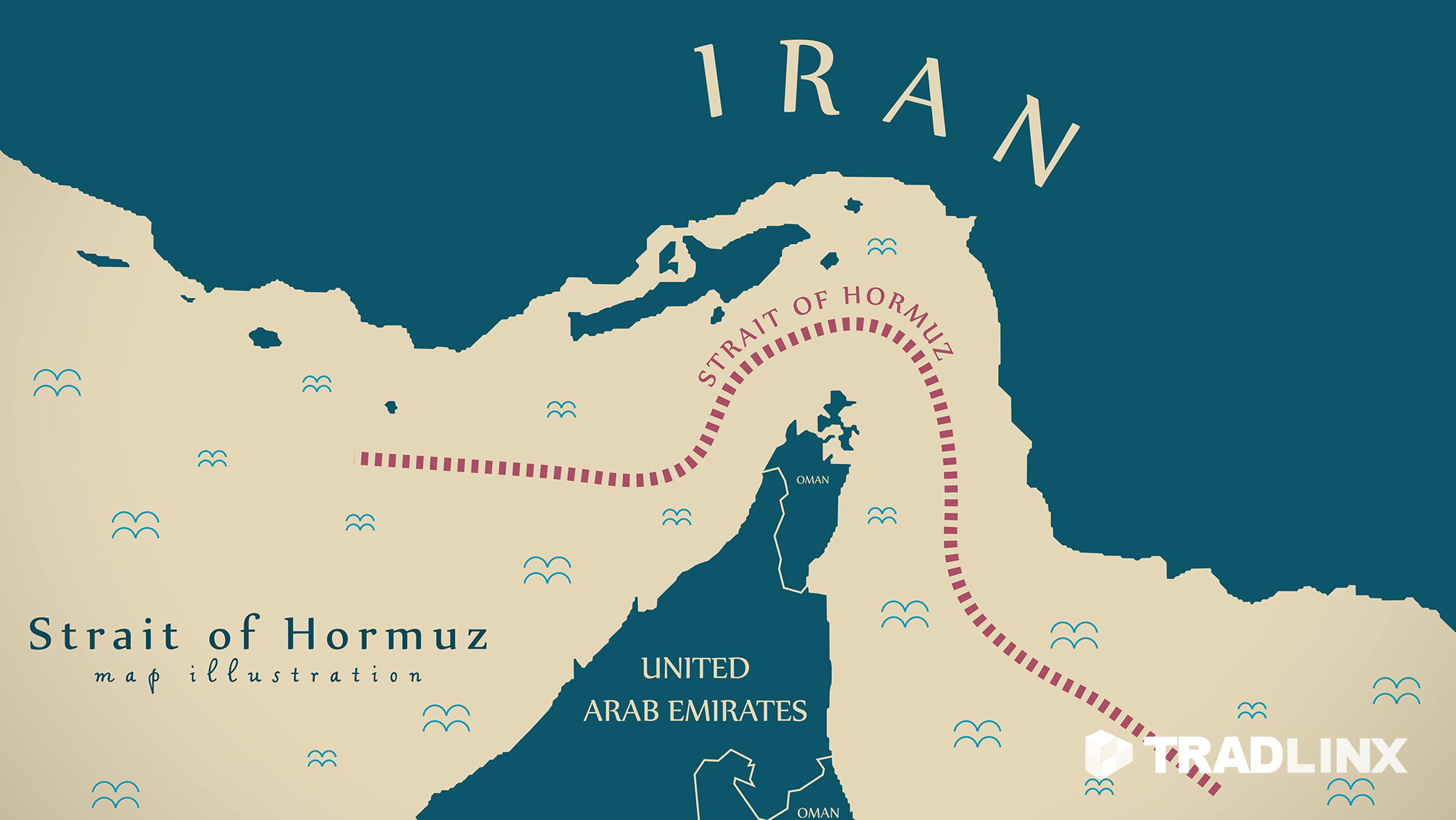

The Strait of Hormuz is the most vital chokepoint in global trade: nearly 20 million barrels of oil and over 33% of global LNG exports pass through this narrow corridor each day. Add to that roughly 40% of global seaborne tonnage, and you get a route that’s critical not just to energy, but to the stability of entire supply networks.

With Iran now threatening to close the Strait following recent military escalations, logistics and supply chain planners face two urgent questions:

- How likely is it that the Strait will actually be closed?

- If it is, how long can global supply chains keep functioning before severe disruptions occur?

This post tackles both. First, we assess the probability of a closure based on political signals, historical behavior, and real-time market data. Then we analyze how long the world’s shipping lanes, inventories, and fuel reserves can sustain operations under different closure scenarios.

How Likely Is It That the Strait of Hormuz Will Be Closed?

Current Situation

- Iran’s parliament has approved a measure to close the Strait, but the final decision rests with the country’s Supreme National Security Council — which has not yet acted.

- Iran has frequently threatened closure in past crises but has never followed through, even during full-scale conflicts.

- This time, the trigger is the recent U.S. airstrikes on Iranian nuclear sites — a significant escalation that has pushed the rhetoric to new highs.

Expert and Market Assessments

- Historical precedent: Iran has never fully closed the Strait, partly because doing so would devastate its own economy and provoke U.S.-led retaliation.

- Economic risks: Blocking Hormuz would halt Iran’s oil exports and likely trigger a global naval response, making a full closure economically and militarily unsustainable.

- Military feasibility: Iran can disrupt shipping temporarily (e.g., via mines or harassment), but sustaining a closure would be extremely difficult.

Probability Estimates

- Prediction Markets: As of June 23, 2025, Polymarket places the odds of closure by June 30 at 40%, and 52% by year-end.

- Analyst consensus: Most shipping and energy analysts still view a complete, sustained closure as unlikely — but risk is significantly higher than in past incidents.

Summary Table: Strait Closure Risk Snapshot

| Factor | Assessment |

|---|---|

| Parliamentary Approval | Yes, passed |

| Supreme Council Decision | Pending |

| Military Capability | Can disrupt, not sustain closure |

| Economic Risk to Iran | Severe revenue loss if closed |

| U.S./Allied Response | Likely immediate & forceful |

| Polymarket Odds | 40% (by June 30), 52% (by EOY) |

| Expert View | Unlikely, but risk rising |

Bottom line: The probability of a full shutdown remains low — but the threat of temporary disruption is very real. For logistics service providers, the window for scenario planning is now.

Historical Near-Closures of the Strait of Hormuz — and Their Logistics Impacts

While the Strait of Hormuz has never been fully closed, history offers several high-stakes moments when global shipping came dangerously close to a standstill. These incidents provide critical insights into how freight markets, naval forces, and supply chains react under threat conditions.

1. The Tanker War (1984–1988)

- Context: During the Iran–Iraq War, both countries targeted oil tankers. Iran threatened to close the Strait after Iraq attacked Kharg Island, a key Iranian oil terminal.

- Logistics Impact: The U.S. launched Operation Earnest Will to escort Kuwaiti tankers, keeping flows open. Brent crude jumped 8%, and war-risk premiums surged.

2. U.S.–Iran Naval Standoff (2008)

- Context: Iranian Revolutionary Guard warned of closing Hormuz if attacked. U.S. Navy positioned carriers in response.

- Logistics Impact: Freight rates spiked 15–25%. Some carriers limited transits to daylight hours, increasing turnaround times and insurance costs.

3. Nuclear Sanctions Standoff (2011–2012)

- Context: Iran vowed to stop “even one drop of oil” if sanctions cut exports. The U.S. deployed a multinational naval flotilla.

- Logistics Impact: Oil futures jumped 4%. Strategic reserves were tapped in Asia and Europe to calm markets.

4. Sanctions Retaliation Threats (2018–2019)

- Context: After U.S. exited the JCPOA deal, Iran warned that “others’ oil will not pass” if its exports were blocked.

- Logistics Impact: 60% hike in war-risk premiums for Persian Gulf transits. Tanker rerouting via the Cape of Good Hope added 10–14 days to voyages.

Summary Table: Near-Closure Episodes

| Period | Trigger Event | Main Threat | Logistics Impact |

|---|---|---|---|

| 1984–1988 | Iran–Iraq Tanker War | Attacks on vessels | U.S. naval escorts; oil +8%; insurance ↑ |

| 2008 | U.S.–Iran naval stand-off | Threat to seal Hormuz | Freight +15–25%; daylight-only transit |

| 2011–2012 | Nuclear sanctions dispute | “Not a drop of oil will pass” | Oil +4%; strategic reserves used |

| 2018–2019 | U.S. sanctions escalation | Oil waivers revoked | Insurance +60%; rerouting adds 10–14 days |

Each of these close calls reveals the vulnerability of maritime logistics to geopolitical shocks — even when the Strait remains technically open. The ripple effects on freight rates, routing decisions, and port congestion often begin long before any formal closure is declared.

How Long Can the World Withstand a Strait of Hormuz Shutdown?

Even if a Strait of Hormuz closure doesn’t happen immediately, logistics professionals need to ask: how long could global supply chains actually function under sustained disruption? The answer depends on the resilience of fuel reserves, inventory buffers, and maritime capacity. Let’s break it down sector by sector.

Oil and LNG Resilience: How Much Buffer Exists?

- OECD Oil Stocks: As of April 2025, commercial and government-held crude and product stocks in OECD countries cover 59.7 days of net oil imports — about 2.5 days below the 5-year pre-COVID average.

- IEA Emergency Reserves: Member nations are required to hold at least 90 days of net import coverage, offering a strategic cushion against immediate supply shocks.

- LNG Vulnerability: LNG lacks a global strategic reserve system. Supply gaps could emerge within 30–60 days in Asia and Europe if alternative shipments aren’t secured promptly.

Implication:

In an energy-only scenario, governments and firms can draw on petroleum stocks to cover up to 60–90 days. However, LNG shortfalls could bite much sooner, especially for countries heavily dependent on Gulf supplies.

Manufacturing Inventory Buffers: How Long Before Plants Halt?

- Days Inventory Outstanding (DIO): Inventory duration varies widely:

- Fast fashion: ~20 days

- Electronics: ~40 days

- Automotive: ~60–90 days

- Just-in-Time Exposure: Lean inventory industries like automotive and electronics typically carry only 30–45 days of component buffers.

Implication:

If parts can’t be rerouted or sourced via air or alternative ports, production stoppages could begin in under 45 days — with severe slowdowns after 60–90 days depending on sector and region.

Shipping Disruption Duration: Delays, Port Congestion & Capacity Loss

Even if vessels can reroute around the Strait of Hormuz, the impact on global shipping schedules is far from minor. Rerouting via the Cape of Good Hope introduces weeks of extra transit time, reduces available vessel capacity, and triggers secondary bottlenecks at major transshipment hubs.

1. Voyage Detours Add 10–14 Days

- Bypassing the Strait forces tankers and container ships to sail around Africa — adding 3,500+ nautical miles and 10–14 days to each journey.

- This reduces effective fleet capacity by 12–15% as vessels spend more time in transit and fewer are available for loading.

2. Port Congestion Compounds the Problem

- Singapore, Rotterdam, and Jeddah would face immediate capacity crunches as vessels bunch up and rebook berths.

- Wait times are projected to rise 3x — from an average of 2–4 days to 6–10+ days in the busiest ports.

3. Insurance & Freight Cost Spikes

- War-risk premiums for transits through the Gulf are already up 60% YoY.

- VLCC charter rates (very large crude carriers) have jumped 100–150% in recent weeks, driving overall freight prices higher across the board.

Implication:

While not a full shutdown, even a partial disruption to the Strait of Hormuz can choke the system. Longer voyage times, cascading port delays, and higher insurance premiums begin to strain just-in-time supply chains within 30 days, with compounding effects the longer the closure persists.

Composite Supply Chain Resilience Timeline: How Long Before Collapse?

Bringing together energy stocks, inventory buffers, and shipping capacity constraints, we can build a practical estimate for how long global supply chains might endure a Strait of Hormuz shutdown. Here’s a consolidated breakdown:

Key Buffers & Estimated Duration

| Buffer Type | Estimated Duration |

|---|---|

| Strategic Oil Reserves | 60–90 days |

| LNG Supply Flexibility | 30–60 days |

| Manufacturing Inventories (Avg.) | 30–90 days |

| Shipping System Buffer | ~30 days before severe capacity strain |

Overall Resilience Estimate

Global supply chains could likely survive a 30–60 day closure of the Strait of Hormuz with disruptions managed through rerouting, inventory drawdowns, and strategic reserves. Beyond that window:

- Energy shortages would become acute in Asia and Europe.

- Manufacturers would face material shortages across electronics, automotive, and chemicals.

- Freight rates would become prohibitively expensive for low-margin cargo.

- Just-in-time logistics networks would face cascading failures and plant shutdowns.

Conclusion: A closure of more than 60 days would likely trigger systemic supply chain breakdowns globally — not just in oil and gas, but in manufacturing, retail, and agriculture.

Scenario Planning for Logistics Professionals

Rather than reacting to a Strait of Hormuz disruption in real time, logistics service providers (LSPs) must proactively plan for multiple disruption levels. Here’s a structured, actionable framework tailored to today’s volatile climate.

Step 1: Define Scenarios Based on Risk Levels

- Base Case: Strait remains open with naval escorts and increased insurance costs.

- Partial Disruption: Transit limited to daylight hours, risk of drone or mine attacks.

- Full Closure: Cape of Good Hope rerouting required for 30–60 days.

- Escalation: Naval confrontation spreads to adjacent ports and regions.

Step 2: Quantify the Impact

| Metric | Base Case | Partial Disruption | Full Closure |

|---|---|---|---|

| Transit Delay | +1–2 days | +4–7 days | +10–14 days |

| Freight Rate Impact | 0–10% | 30–60% | 100–150% |

| Insurance Premiums | 0–5% | 20–40% | 60–100% |

| Fleet Capacity Reduction | 0–3% | 5–8% | 9–15% |

| Port Congestion (Wait Time) | +0–1 days | +2–4 days | +6–10 days |

Step 3: Prepare Adaptive Strategies

- Route Flexibility: Pre-book Cape of Good Hope slots and leverage secondary hubs like Duqm or Salalah.

- Blank Sailings & Prioritization: Defer low-priority cargo and reposition high-efficiency vessels.

- Contract Adjustments: Add force majeure clauses and dynamic risk-surcharge mechanisms.

- Inventory Buffering: Increase safety stock by 20–30% for vulnerable SKUs.

- Modal Diversification: Pre-arrange air/rail contracts for urgent goods.

zPro Tip:

Use scenario-based simulations and digital twins to run “what-if” tests. Cross-functional crisis drills can reveal supply chain blind spots ahead of a real-world shock.

Conclusion: Resilience Has a Deadline

The Strait of Hormuz isn’t just a geopolitical flashpoint — it’s a logistical lifeline. While historical precedent suggests that a full closure is unlikely, current military tensions have pushed closure odds above 50% in some prediction markets. Even a limited disruption could send freight costs soaring, reroute vessels for weeks, and leave just-in-time inventory networks exposed.

Scenario planning, inventory diversification, and dynamic routing strategies are no longer optional. Global supply chains are only as strong as their weakest chokepoint — and Hormuz remains the most critical of them all.

Key Takeaways for Logistics Professionals

- Buffer timelines matter: Energy supplies may last 60–90 days, but logistics strain builds after just 30.

- Shipping isn’t plug-and-play: Reroutes reduce fleet capacity by up to 15% and overload alternate ports.

- Plan for probabilities, not certainties: Scenario-based contingency strategies can limit cost blowouts and customer disruption.

- Be proactive, not reactive: Resilience is built before crisis hits — through data, collaboration, and diversification.

For shippers, carriers, and supply chain strategists, the next disruption may not come with a warning. But preparedness can turn a geopolitical shock into a manageable detour — instead of a supply chain catastrophe.

Further Reading & Data Sources

- EIA – Strait of Hormuz Oil Transit Data

- UNCTAD – Review of Maritime Transport 2023

- IEA – Oil Stocks of Member Countries

- Kpler – Strait of Hormuz Risk Assessment

- Netstock – Industry Inventory Days Benchmarks

- UNCTAD Guidebook – Scenario Planning in Maritime Logistics

- Middle East Monitor – Iran Closure Announcement

❓ Strategic Logistics Questions Answered

How long can global supply chains survive a Strait of Hormuz closure?

➡ Most supply chains can withstand a 30–60 day disruption. Energy stockpiles last up to 90 days, but shipping capacity and just-in-time inventories strain within 30.

What industries are most at risk if the Strait of Hormuz is closed?

➡ Automotive, electronics, and chemical sectors rely on Gulf-origin cargo and lean inventories, making them especially vulnerable to transit delays and fuel price spikes.

Will oil and gas prices surge if the strait closes?

➡ Likely yes. Brent crude and LNG rates could surge 50–150% due to rerouting and insurance costs, impacting both commodity markets and transport costs.

What logistics strategies can mitigate the impact of a closure?

➡ Scenario-based planning, diversified routing (e.g., via Cape of Good Hope), inventory buffering, and updated force majeure clauses are key defense tools.

Has the strait ever been closed before?

➡ No full closure has occurred, but past threats (e.g., 1987, 2012, 2019) triggered freight rate spikes, convoy escorts, and rerouting — offering a roadmap for future impacts.

Why overpay for visibility? TRADLINX saves you 40% with transparent per–Master B/L pricing. Get 99% accuracy, 12 updates daily, and 80% ETA accuracy improvements, trusted by 83,000+ logistics teams and global leaders like Samsung and LG Chem.

Prefer email? Contact us directly at min.so@tradlinx.com (Americas) or henry.jo@tradlinx.com (EMEA/Asia)

Leave a Reply